History

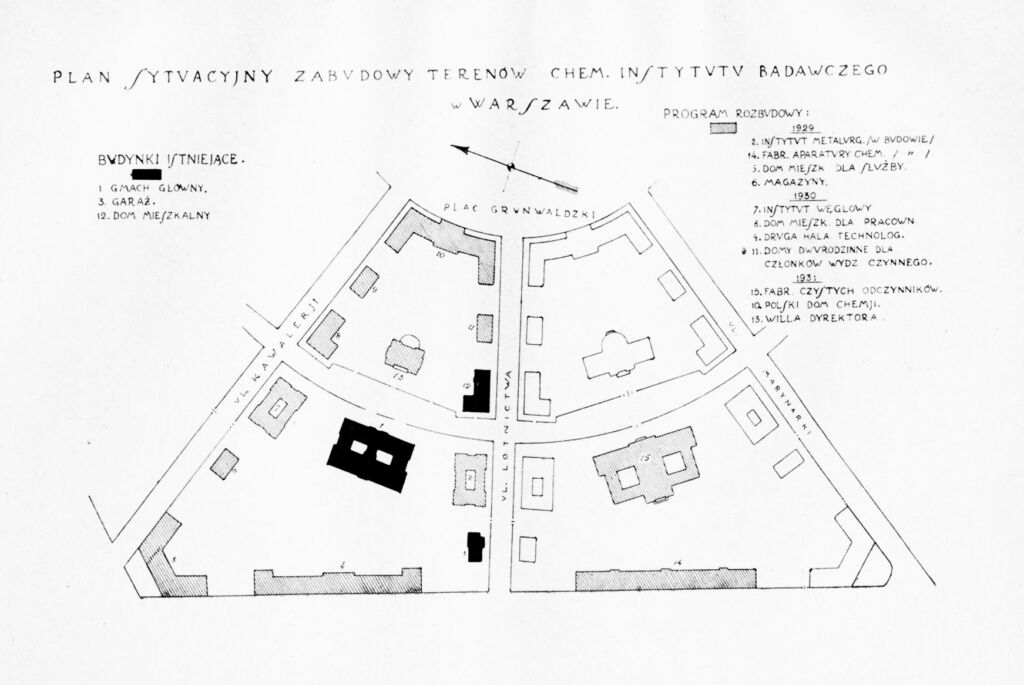

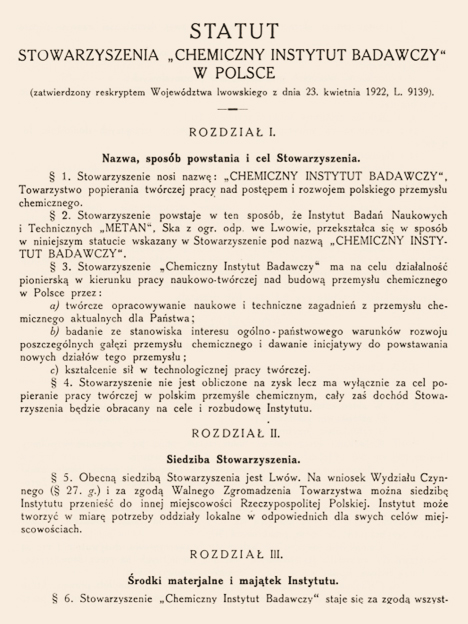

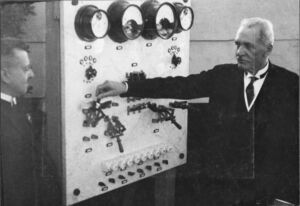

Industrial Chemistry Institute has existed since 1916, when, on the initiative of Professor Ignacy Moscicki, Poland’s first chemical research institute (METAN company) was established in Lvov, transformed in 1922 into the Chemical Research Institute (ChIB). A few years later, in 1926, the Institute’s headquarters were moved to Warsaw.

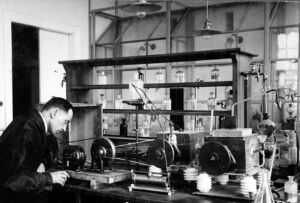

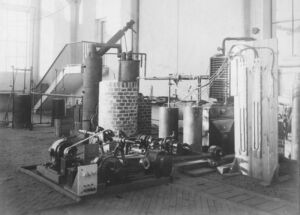

The task of the Chemical Research Institute was scientific activity aimed at building and developing the Polish chemical industry, with particular emphasis on the use of domestic raw materials – coal, clay and rock salt. The Institute’s most important achievement at the time was the development of a technology for obtaining synthetic rubber (KER), the commissioning of a plant for its production in Poland (as the third in the world after Germany and the Soviet Union) and the sale of licences, on the basis of which a number of plants were built abroad.

After the interruption caused by the Second World War, the scientific and research activities of the ChIB were reactivated as early as 1945 as part of the Institute of Chemical Industry, from which the Central Institute of Industrial Chemistry was established in 1948, subsequently transformed in 1951 into the Institute of General Chemistry – a departmental institute of the Ministry of Chemical Industry. In 1971, the Institute of Industrial Chemistry was formed from a merger of the Institute of General Chemistry and the Institute of Plastics. In 1990, it was named after Professor Ignacy Moscicki. In 1990, it was named after Professor Ignacy Moscicki.

The achievements of the post-war years amount to approximately 2,000 patents, sets of technological development tools and technical devices obtained on industrial devices in Poland and abroad, dozens of devices included in the database licensed by the IICI.

The development and global implementation of Polish technology for producing cyclohexanone from benzene, a mixture of c-none and c-nol, and caprolactam are another of the Institute’s spectacular achievements. The first pilot plant was launched at the Nitrogen Plant in Tarnów in 1962.

Among subsequent implementations, it is also worth mentioning the technology for obtaining TDI (the main raw material for the production of polyurethanes) – an innovative TDA phosgenation process, purchased by BASF (2012); PVC nanocomposites – industrial installation in Anwil SA (2015) or the development of a technology for the co-hydrogenation of petroleum fractions with vegetable oils or animal fats as a source of biocomponents for PKN Orlen S.A. diesel fuel (2019) and the technology for obtaining liquid hydrocarbons from natural oils (HVO technology – 2022).

A milestone in the pharmaceutical industry was the introduction of the antileukemia drug BIODRIBIN®, based on cladribine produced at the Institute, into production in the 1990s. In 2000, BIOTON S.A. implemented a proprietary technology for producing human insulin and its finished forms, the GENSULIN® series. This is the first Polish drug produced using genetic engineering.

Currently, the Institute offers comprehensive development and implementation of technologies for the production of medicinal products and active pharmaceutical ingredients (APIs). These are manufactured according to the highest GMP, CEP, and ASMF standards, based on proprietary technologies and implementations. The Institute is a key API manufacturer in the Polish market (second in terms of production volume according to IQVIA) and offers eight active pharmaceutical ingredients.

From 1 April 2019. The Institute became part of the Łukasiewicz Research Network, adopting the name Łukasiewicz Research Network – Industrial Chemistry Institute.

On 1 June 2020, the following belonging to the Łukasiewicz Research Network: the Pharmaceutical Institute (Łukasiewicz – IF) and the Institute of Biotechnology and Antibiotics (Łukasiewicz – IBA) were incorporated into the Industrial Chemistry Institute.