Chemical technology research group

Scaling and Pilot Section

We specialise in research and design of unit processes and technological lines, as well as in upscaling organic synthesis and separation processes for the chemical industry.

Our comprehensive approach combines innovative technologies with modern, computer-assisted research methods, providing customers with effective, scalable and ready-to-implement solutions.

We are the only company in Poland that is a member of the UNIFAC Dortmund consortium, with advanced tools for predicting liquid-vapour equilibria in real systems. Our physicochemical databases, covering pure substances, two-component VLE equilibria, SLE equilibria and azeotropic data, enable precise process modelling and support the development of efficient industrial technologies.

RESEARCH OFFER:

- laboratory and large-scale laboratory testing and analysis of new synthesis pathways, including hydrogenation, dehydrogenation, alkylation, isomerisation, coupling, oxidation, etc. Research on the course of chemical reactions is conducted under pressure conditions, both periodically and continuously, in reactors with a fixed catalyst bed in order to improve them, test new catalysts or new solutions;

- processes of separation and purification of mixtures using methods such as: rectification (under vacuum conditions up to pressures of 10 barG), crystallisation (solvent, from alloy), extraction (including in supercritical solvents, e.g. CO2), extraction using ionic liquids or DES solvents, membrane processes;

- synthesis and applications of ionic liquids (IL) and deep eutectic solvents (DES) in separation processes, catalytic processes and others;

- computer modelling in commercial process simulators (Chemcad), extended with additional packages for predicting physicochemical equilibria (modelling of steady-state operation of chemical reactors, column heat and mass transfer apparatus, gas purification processes) in order to estimate the costs and efforts involved in process upscaling;

- integration of implemented solutions for existing installations (including rescaling), identification of bottlenecks in operating installations;

- correlation and implementation of experimental data into models, prediction of physicochemical properties, and validation with actual experimental data

We provide comprehensive analysis of materials and products – from chemicals and polymers to cosmetics and industrial materials. We combine modern laboratory facilities with many years of expert experience, carrying out both application testing and advanced physicochemical, chromatographic and spectroscopic analyses.

We offer a comprehensive package of quality, validation and development testing, supporting manufacturers in improving their technology, quality control and compliance with national and international standards.

ANALYSIS OF ORGANIC COMPOUNDS, POLYMERS AND PLASTICS:

- identification of organic compounds, polymers, plastics, paints, glues, binders, etc. by spectrophotometric and chromatographic methods;

- identification and structure studies of non-volatile organic substances, e.g. synthetic and natural polymers, biochemical and geochemical products using the Py/GC/FTIR method;

- determination of average molecular weights and molecular weight distribution of polymers by gel permeation chromatography (GPC);

- analytical studies of organic compounds using FTIR and UV-VIS absorption spectrophotometry methods;

- studies of the curing and cross-linking of macromolecular compounds using the FTIR method (determination of functional groups);

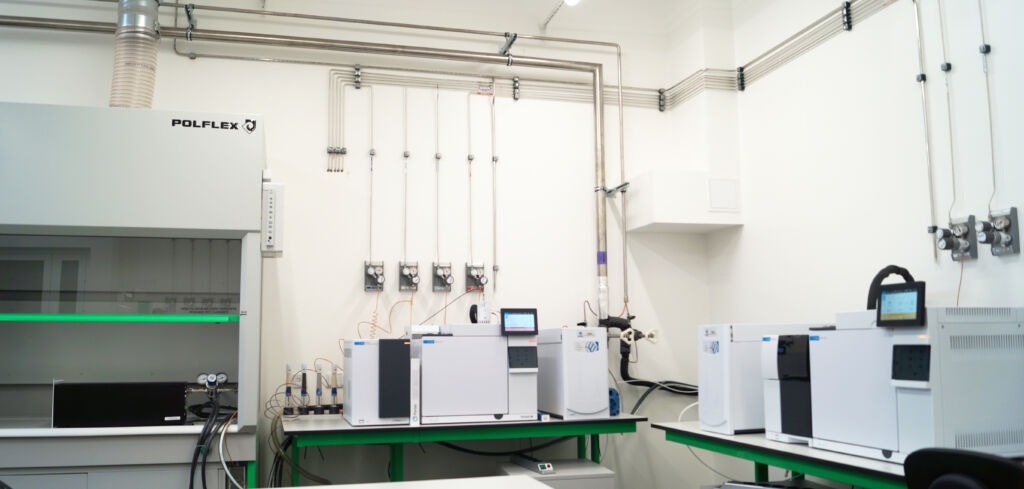

- compositional analysis (identification of volatile components) of mixtures of organic compounds using GC/MS and GC/AED methods;

- determination of trace amounts of toxic substances (monomers and solvents) in plastic and other products by GC method using head-space technique, flame ionization detectors (GC/FID) and atomic emission detectors (GC/AED) and electron capture detectors (GC/ECD);

- determination of C1–C3 alcohol content in household chemical products and pharmaceutical products using the GC/FID method;

- determination of the content of organic acids, hydrocarbons, alcohols, esters and ketones in gas samples by GC/FID;

- testing the migration into food simulants and the emission of trace amounts of substances from plastic products into the atmosphere using spectrophotometric and chromatographic methods;

- control of the purity of chemical raw materials and testing of technological processes using UV, GC, FTIR and AAS methods.

CONTACT

Dominika Kubica, PhD. Sc. Eng.

phone +48 517 883 165

dominika.kubica@ichp.lukasiewicz.gov.pl

Małgorzata Walkiewicz, M. Sc.

phone +48 517 883 168

malgorzata.walkiewicz@ichp.lukasiewicz.gov.pl

CHEMICAL ANALYSIS, PURITY TESTING AND IDENTIFICATION

- determination of volatile odour compounds and aromas using GC-MS

- determination of organic compounds in cosmetic raw materials using gas chromatography methods (GC/MS, GC/FID)

- identification of volatile organic compounds in various matrices using SPME-GC/MS and HS-GC/MS techniques

- analysis of gas samples using GC/MS and GC-FID/TCD methods

- analysis of the identity and purity of chemical substances using GC/MS, HPLC, and GC/FID methods

- analysis of solvent composition using gas chromatography methods

- determination of cations and anions in aqueous solutions and in gas using ion chromatography (IC)

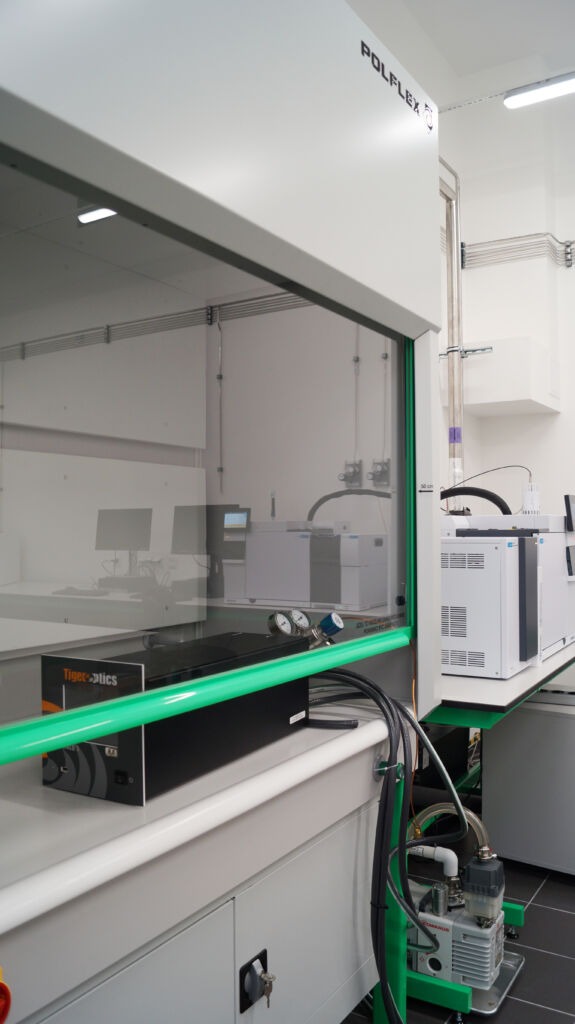

- determination of water content in hydrogen using the CRDS method

- determination of water content by Karl Fischer coulometric titration according to PN-EN ISO 12937 and ASTMD 6304

- determination of water content by Karl Fischer potentiometric titration

- determination of bromine index by coulometric titration according to ASTMD1492

- determination of bromine number by coulometric titration

- determination of density – hydrometer method according to ASTMD 1298 and PN-EN ISO 3675

- determination of density – pycnometer method

- determination of free water content according to ASTMD 2709

- determination of the content of unsaponifiable substances in vegetable and animal oils and fats according to PNISO 3596

- marking of insoluble contaminants in vegetable and animal oils and fats according to PN-EN ISO 663

- determination of iodine value according to PN-EN 14111

- determination of the peroxide value in vegetable and animal oils and fats according to PN-EN ISO 3960

- determination of saponification value according to PN-C-04043

- determination of acid value according to PN-EN 14104 and PN-ISO 660

- determination of water content and volatile substances in vegetable and animal oils and fats according to PN-EN ISO 662

- aniline point determination according to ASTMD 611

- determination of asphaltene content according to ASTMD 3279

- determination of the flow temperature according to PN-EN ISO 3016

- determination of the refractive index according to ASTMD 1218

We have a research hall with a volume of over 7,500 m³ in the low part, with a maximum height of over 13 m, and over 16 m in the tower part. In 2025, as part of the National Reconstruction Programme, the building underwent a thorough renovation, gaining, among other things, new windows, including those with increased fire resistance in the tower section, and a new façade.

- Research hall equipped with typical technological media: heating steam, heating oil, glycol, vacuum, demineralised water.

- Steam is provided by two technical steam generators, each with a capacity of 96 kW, which translates into a total steam output of 240 kg/h, at pressures of 6 bar in the low part and 8 bar in the tower part.

- Compressed air from an Atlas Copco CD 17+ oil compressor with dryer. Maximum working pressure of the compressor is 13 bar, and maximum pumping capacity is 68 m³/h.

- Vacuum from a water pump, approx. 20 mm Hg.

- Demineralised water from the demineralisation station.

- Both the low and tower sections are single-storey, with mezzanines spaced away from the external walls, on a self-supporting steel structure, with steel working platforms. This layout allows for any adaptation of the space, including the installation of tall systems running through several levels of platforms.

- In the tower section, we have a vacuum distillation installation with a capacity of 300 dm3, with the possibility of heating to approx. 170°C and a vacuum of approx. 5-2 mm Hg. The vacuum is obtained in a mixed manner using a water pump and steam traps.

- In addition, the hall is equipped with steel and enamelled reactors of various capacities, ranging from 30 dm³ to 2,000 dm³. The hall also houses a filtration unit, a filter centrifuge, a dryer, ball and cutting mills, transport trolleys, lifts and a mechanical workshop.

The hall has always been used for small-scale production of products developed at the Institute and for scaling chemical processes.

Examples of products manufactured in the hall include boatbuilding adhesive for cold bonding of boatbuilding timber or other wood and wood-like materials, colacrylic adhesive for the production of self-adhesive products, a preparation for the impregnation, renovation and maintenance of buildings, monuments and tombs made of sandstone, granite, terrazzo, etc.

Currently, PBDMS elastomer is produced periodically for use in the manufacture of personal protective equipment designed to absorb impact energy.

Among other things, research was conducted in the hall as part of POIG 01.03.01-00-010/08, developed at the Institute, on the production complex for acrylic acid and acrylic esters.

We offer technology transfer from the laboratory to the industrial pilot scale, production of information batches, and experimental production.