Polymer technology research group

Advanced Polymer Materials Section

We design modern polymer materials with a wide range of properties – from resistant composites to smart coatings.

We combine chemistry, materials engineering and polymer technologies to support industry in increasing efficiency, introducing innovations and creating products ready for use in areas such as construction, energy and medicine.

CONTACT

Milena Kurkowska, PhD. Sc. Eng.

phone +48 453 056 322

milena.kurkowska@ichp.lukasiewicz.gov.pl

We specialise in the synthesis of modern polyurethanes and silicone urethanes, the design of smart coatings, and the development of composites for demanding industrial applications.

Our solutions are used in the construction industry, energy sector, materials engineering, and 3D printing technologies, among others.

Research offer:

- synthesis of polyurethanes and silicone-urethanes, etc., cross-linked by moisture from the air (e.g. putties and sealants);

- developing innovative roof waterproofing systems that respond to changes in humidity with intelligent thermal management;

- synthesis of aqueous polyurethane dispersions, including hybrid ones: silicone-urethane, acrylic-urethane, silicone-acrylic, acrylic-alkyd, especially for use as eco-friendly coating materials;

- modification of bitumens, coal tars and hydrocarbon resins with isocyanates to improve thermal resistance in the upper and lower usage ranges, resistance to environmental factors and mechanical properties;

- development of associative polyurethane thickeners improving the rheological properties of paints, varnishes, adhesives, sealants, pastes and pigment dispersions;

- selection of polymer plasticisers for PVC;

- obtaining solvent-free and water-dispersible binders for UV-cured coatings;

- development of silicone urethanes for specific applications such as: living cell scaffolds; solid polymer electrolytes; membranes for separating liquid and gas mixtures;

- selection of polymer nanopowders as impact modifiers for powder coatings and polymer materials;

- smart polymer coatings for special applications, including: self-repairing, electromagnetic radiation shielding, self-cleaning, superhydrophobic, etc.;

- developing and obtaining reticulated glassy carbons for specific applications: filtration, energy storage, gas adsorption, metallurgy, etc.;

- polymer consumables used in 3D printers, mainly FDM printing: selection and modification of anti-adhesive materials for tables and DLP printing with the selection of reaction mixtures.

We work with modern equipment for advanced thermal, thermomechanical and microscopic analysis.

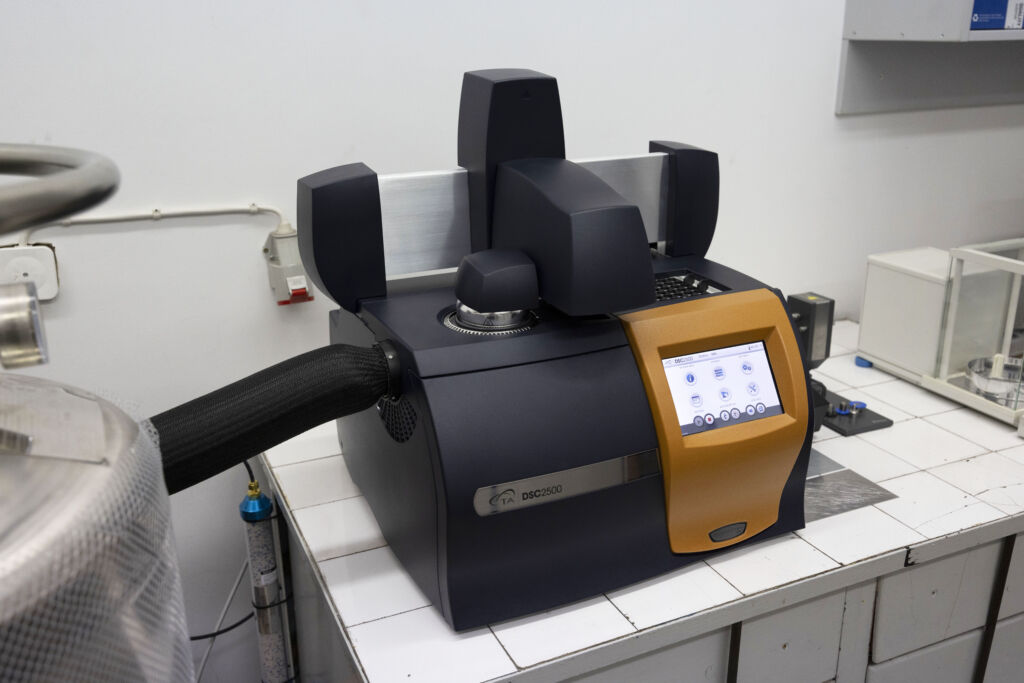

DSC (Differential Scanning Calorimeter) – Discovery DSC 2500 LN, TA Instruments – a differential scanning calorimeter enabling direct measurement of heat flow and temperatures of physicochemical transitions of materials in the range of (-180) – (+300)°C using patented Tzero™ technology:

glass transition temperature (Tg),

melting point, crystallisation point, polymorphism,

heat capacity Cp,

determination of enthalpy ΔH of endothermic and exothermic reactions,

Thanks to the use of temperature modulation technology (MDSC®), it is possible to separate overlapping effects and distinguish between reversible and irreversible changes.

DMTA (Dynamic Mechanical Thermal Analyser) – Discovery DMTA 850, TA Instruments – a dynamic thermomechanical analyser that allows testing in a wide temperature range

(-150°C)-(+600°C), in the force range from 0.1mN to 18N in oscillation in the frequency range of 0.001-200Hz. The device allows for analysis in a wide range of mechanical deformations:

bending of samples in a single and dual cantilever system with samples fixed at the ends,

with low-friction support at both ends, known as three-point bending,

– stretching fibres, films and flat products,

– shearing,

– compression,

– analysis of powders in a cuvette in a dual cantilever system,

– softening point analysis;

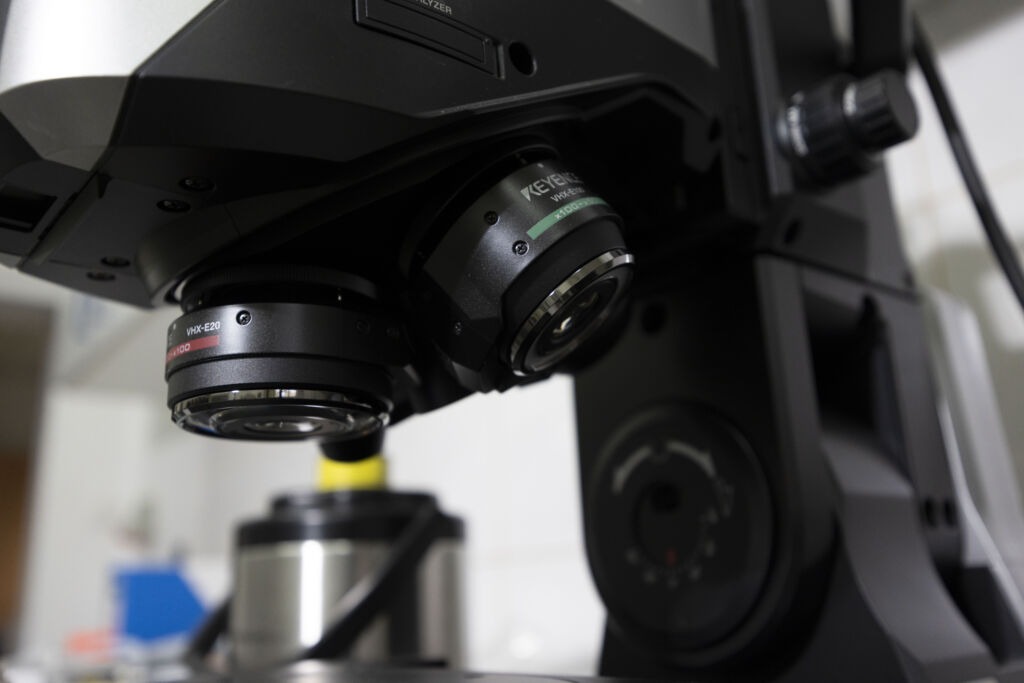

The advanced Keyence VHX-X1 digital microscope with lenses ranging from 5-50x macro to 2500-6000x for detailed analytical applications with advanced profiling function, including the determination of characteristic roughness parameters (Ra, Rz, Sa, Sz), equipped with fully compatible attachments: heating/cooling (Linkam) operating in the range (-196°C)-(+420°C) and a fluorescence adapter (Nightsea) – excitation range 360-540 nm;

Phrozen Sonic 4K 2022 – a DLP 3D printer based on liquid photopolymer resins;

Zmorph – FDM 3D printer.

Research into selected properties of coating materials (paints and varnishes):

Gloss based on PN-EN ISO 2813 standard,

Hardness: Persoza and Koniga based on PN-EN ISO 1522 and pencil based on PN-EN 13523-4,

Impact resistance based on the falling weight method according to PN-EN ISO 6272-1,

Abrasion resistance based on the abrasive paper disc method according to PN-EN ISO 7784-2 and the Taber method according to PN-EN ISO 5470-1.

Scratch resistance based on PN-EN ISO 1518 standards,

Water resistance based on the Łukasiewicz – ICI own method based on PN 76 C-81521 and assessment according to PN-EN ISO 4628-2,

Adhesion – Cross-cut method based on PN-EN ISO 2409,

Flexibility based on bending test according to PN-EN ISO 1519,

Wetting angle, drop placement, surface free energy and surface tension of liquids (Kruss goniometer),

Thickness based on the acoustic method according to PN-EN ISO 2808,

Compressibility based on PN-EN ISO 1520 standard.

Other research methods:

- Minimum coating formation temperature (MTTF) based on standard PN-90/C-89415 (RHOPOINT Instruments MTTF-90),

- Dry residue – Łukasiewicz – ICI own method,

- Mechanical stability of aqueous dispersions and suspensions in a laboratory centrifuge at several temperatures, range (+5 °C )-(+40°C),

- Viscosity: as a function of shear rate or temperature (Kinexus rheometer)

- Viscosity measured with a Brookfield rotational viscometer,

- Viscosity measured using a flow cup based on PN-81/C-81508,

- Ściekalność w oparciu o normę PN-80/C 81539, rozlewność w oparciu o normę PN-89/C 81507,

- Particle size and assessment of the distribution of these sizes (polydispersity) in the range from 5 nm to 5 μm (Malvern apparatus),

- Measurement of the electrokinetic zeta potential (ζ) of particles (Malvern apparatus).