Chemical technology research group

Electrochemical Processes Section

We conduct advanced research and development work in the field of electrochemical and chemical processing of materials, with particular emphasis on the recovery of metals and their compounds of high utility value.

Our activities encompass a comprehensive approach – from analysing the composition of the material under investigation, through developing dedicated processing procedures, to implementing effective and selective recovery methods.

CONTACT

Katarzyna Skrzypczyńska, PhD. Sc. Eng.

phone +48 453 056 292

katarzyna.skrzypczynska@ichp.lukasiewicz.gov.pl

Research offer:

METAL RECOVERY AND MATERIAL PROCESSING:

- developing material processing procedures, including pre-treatment and leaching, to obtain solutions with a high metal content.

- chemical and quantitative analysis of materials to determine their raw material potential and select optimal recovery methods.

- electrochemical and chemical recovery of metals with high efficiency and selectivity, enabling the production of commercial products.

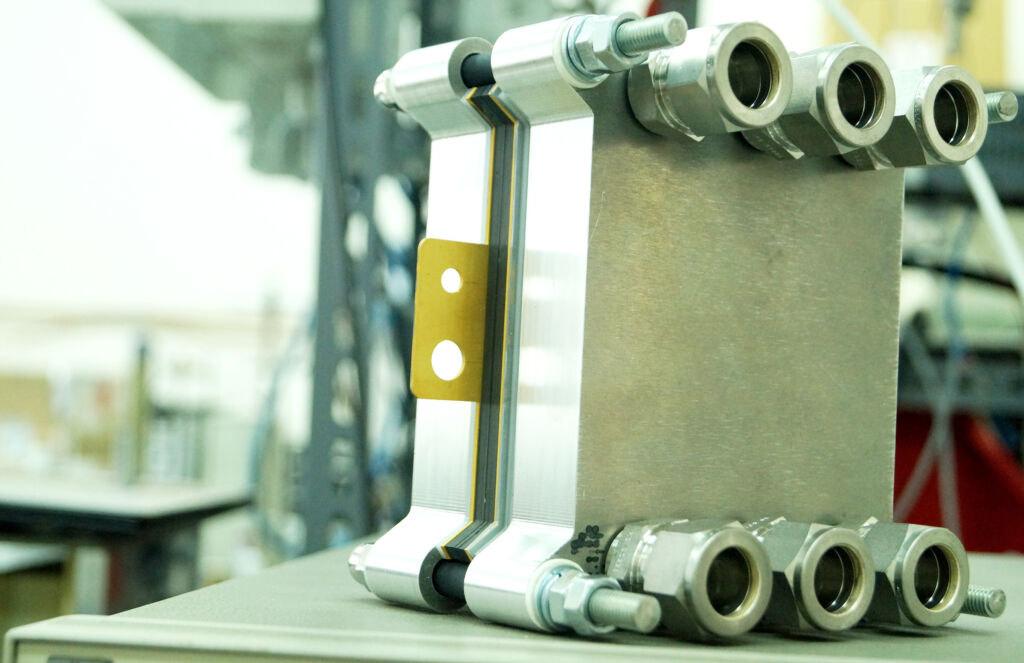

RESEARCH ON PEMFC FUEL CELLS:

- electrochemical production of catalytic nanoparticles deposited on a carbon carrier

- preparation of test MEA systems using the supplied catalysts

- design and testing of individual PEMFC cells (5–100 cm²) and design and testing of new cell and stack components

- testing fuel cell stacks with a power output of up to 1 kW, including stationary UPS and mCHP applications

- testing, recycling of PEM fuel cells, and development of new electrochemical methods for determining contaminants in hydrogen

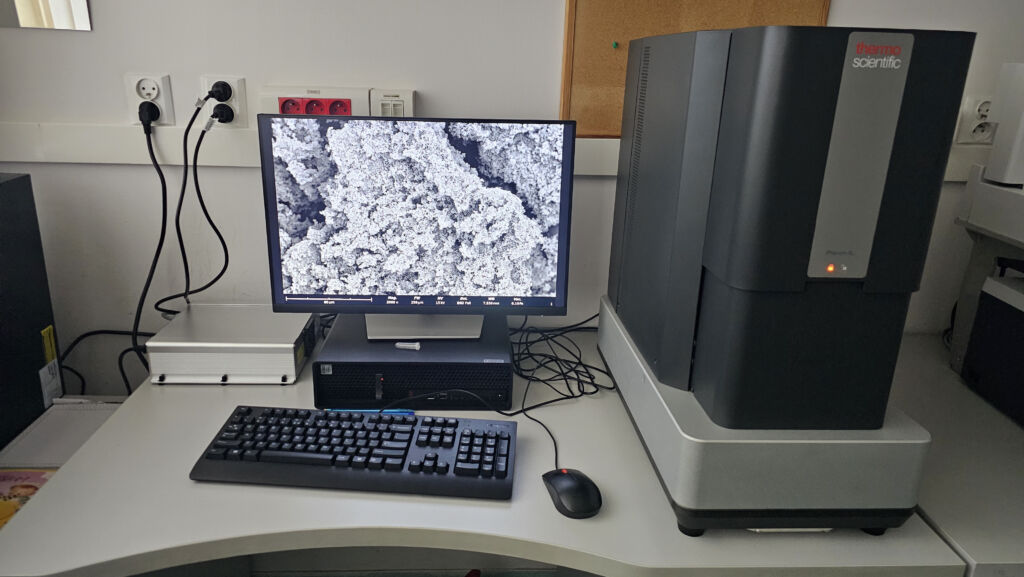

- The Phenom XL scanning electron microscope with EDS microanalyser enables detailed characterisation of the microstructure of the tested materials, allowing their morphology to be observed in high resolution. The EDS detector allows for precise analysis of the elemental composition of samples, which is crucial for assessing the quality of materials and chemical processes. This device enables fast and accurate acquisition of data necessary for scientific research, development work and quality control.

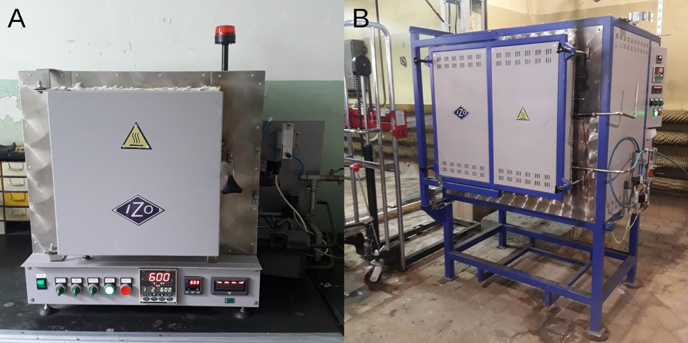

- We have modern chamber furnaces with capacities of 3.05 kW, 16.1 kW and 28.9 kW, which enable precise heat treatment of materials in a wide range of temperatures. The equipment allows for controlled heating, sintering and calcination processes, ensuring repeatability and high efficiency of laboratory testing and development work. Higher furnace capacities enable the processing of larger samples and the implementation of semi-industrial scale projects.

- The Kavalierglass leaching apparatus with the PKM-300L pressure press, Eko-Press, enables effective and precise separation of solid and liquid phases in chemical and electrochemical processes. The device allows for obtaining high-quality solutions with a high concentration of active ingredients, which is essential in research on metal recovery and sample preparation for further analysis. Thanks to its robust design and pressure control, the leaching machine ensures repeatable results and high laboratory efficiency.

- Electrochemical stations (potentiostats) come from renowned manufacturers such as Autolab, Solartron, Voltalab, Metrohm Autolab, and CH Instruments. The devices allow experiments to be conducted at a maximum current of up to 1 A and a voltage of up to 10 V, with the possibility of using direct and alternating current techniques, constant voltage techniques and impedance spectroscopy. This enables precise studies of the kinetics of electrochemical processes and optimisation of metal recovery, ensuring repeatable results and high efficiency of laboratory work.

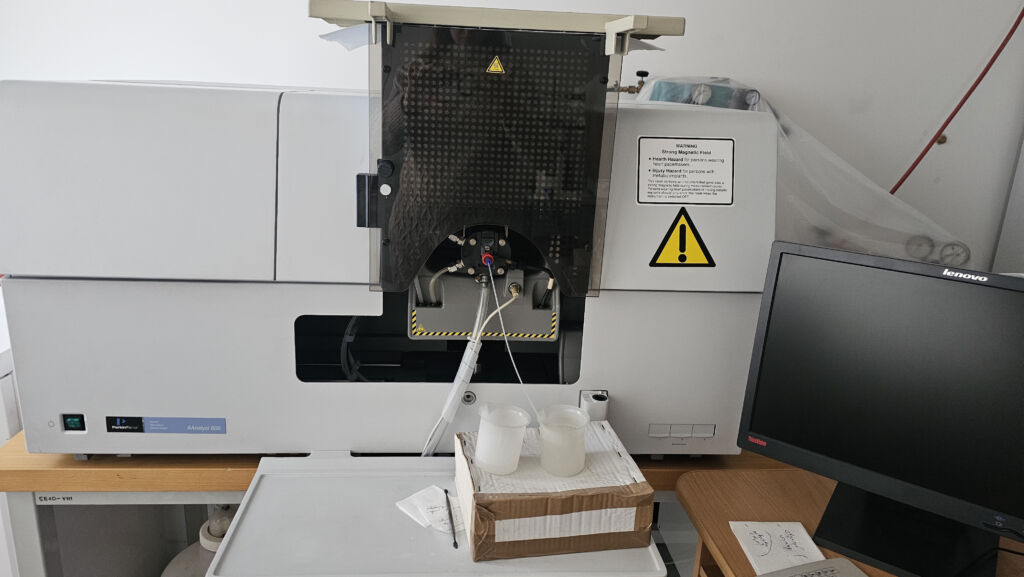

- The Analyst 800 chemical analyser from PerkinElmer enables precise and rapid chemical analysis of liquid and solid samples. The device allows for accurate determination of elemental composition and concentration of chemical compounds, which is crucial in metal recovery research, material quality control and development work. Thanks to modern technology, the analyser ensures repeatable results and high efficiency of laboratory testing.

- The Discovery 2.0 microwave reactor is a modern research tool that allows for fast and precise chemical synthesis and material analysis under controlled microwave energy conditions. Thanks to its innovative control system and high repeatability of results, Discovery 2.0 significantly speeds up laboratory work, minimising reagent and energy consumption. It is the ideal solution for research teams seeking to effectively develop new materials, drugs and chemical technologies.