Polymer technology research group

Polymer synthesis and modification section

We create advanced polymer materials designed for specific industrial applications.

We develop new synthesis technologies and modify existing polymers, increasing their functionality and efficiency in production processes, allowing companies to introduce innovative and efficient solutions.

When designing new materials, we consider the entire product lifecycle—from raw materials, including recycled and renewable sources, through use and safety, to reusability. Our solutions support the circular economy and help companies achieve their sustainability goals by reducing environmental impact and increasing resource efficiency.

Research offer:

ADVANCED POLYMERS, COMPOSITES AND LAMINATES: modern production technologies from renewable and recycled raw materials, including building materials with low energy and material consumption.

- technologies for obtaining and modifying thermosets: polyester resins – including those with special properties, liquid, low-melting, solid epoxy resins, elasticizing agents for epoxy resins; chemical and physico-chemical preparation and modification, including composites, nanocomposites and laminates; synthesis of auxiliary agents for selected structural resins – including plasticizers obtained from by-products and waste.

- urea, melamine, phenol-formaldehyde resin technologies – including melamine foams and resins with reduced formaldehyde emission

- building materials with low energy and material consumption – foam materials

- technologies for obtaining polyurethane materials – new types of insulating materials (modular construction), flexible polyurethane foams

- research on reducing the flammability of plastics (polyethylene, polypropylene, polyurethanes, polyesters, epoxies, polystyrene and others)

- obtaining halogen-free flame retardants, including flame retardant additive systems such as Intumescent Flame Retardant Systems (IFRs)

- monomers for the synthesis of plastics obtained from renewable or recycled raw materials, biodegradable polymers, with applications in the packaging industry

- design and production of functional biopolymer composites, including: bioactive and biodegradable foamed materials, biofilms and PUR/PIR biofoams,

- new polymer materials: functional polymers with the addition of structure modifiers or functionalized hybrid natural or waste fillers

- thermoplastic, solvent-free hot-melt adhesives: polycondensation adhesives (polyamide, polyester), adhesives based on PP, PE, EVA, APAO copolymers and block rubbers (SIS, SBS, SEBS), adhesives used in the leather, electrical, construction, furniture, packaging and electronics industries

- water-based polyester resin technologies

- obtaining ecological fungicides and bactericides; modification of polymers for their hygienization

- plastic recycling technologies

- research on the controlled release of active ingredients from polymer matrices

- optimization of existing technologies in the field of bioactive materials and biocomposites

POLYMER FUNCTIONAL COATINGS: coatings with special properties including: antibacterial, flame retardant, gas barrier, hydrophobic, shielding

- coatings with antifungal and antibacterial properties

- coatings with flame-retardant or fire-protective properties

POLYMERS AND BIOPOLYMERS WITH PROPERTIES: antibacterial, antifungal and antioxidant, with applications in the food, medical, cosmetic and other industries

- obtaining ecological fungicides and bactericides based on natural compounds

- isolation and purification of bioactive compounds from plant raw materials and pharmaceutical substances

- research on the sorption of active substances on polymer, biopolymer and mineral carriers with modified surfaces

SUSTAINABLE AGRICULTURE: ecological plant protection products and pesticide minimization

- Superabsorbent polymer (SAP) technologies – controlling water retention in the soil, gradually releasing nutrients, absorbing harmful substances

- natural fertilizer technologies

- natural fertilizer technologies

OPTIMIZATION OF CHEMICAL PROCESSES: processing, synthesis, modification of plastics.

POLYMER MATERIALS ANALYTICS: comprehensive polymer analytics, processing properties, performance parameters, microplastics analysis and more

- comprehensive flammability analysis of materials: oxygen index, vertical and horizontal flammability, cone calorimeter tests, thermogravimetric tests coupled with a mass spectrometer.

- research using IR microscopy and Raman microscopy – including analysis of microplastics.

- characteristics of polymer resins: viscosity, density, acid number, hydroxyl number, curing time, temperature peak and others.

- mechanical and strength tests – bending, compression, tension.

Cone calorimeter:

- Standard: ISO 5660

- Measurement of the amount of heat and smoke released during combustion.

- Parameters:

– Heat of combustion (HRR – Heat Release Rate),

– Time to ignition,

– Total heat release (THR),

– CO/CO₂ release,

– Smoke production rate (SPR).

– Allows for simulation of fire conditions and assessment of material combustion intensity.

Oxygen index, (LOI – Limiting Oxygen Index)

- Standard: ISO 4589

- Determination of the minimum oxygen concentration in the oxygen-nitrogen mixture needed to support the combustion of the material.

- Rule of thumb: The higher the LOI, the more difficult it is for the material to ignite and burn.

- A simple and quick method for assessing flammability.

UL-94 chamber

- Standard: UL-94 (Underwriters Laboratories)

- Classification of materials based on their behavior when burned vertically or horizontally.

- Methods:

– UL-94 HB (horizontal burning),

– UL-94 V-0, V-1, V-2 (vertical burning).

- The assessment includes:

– burning time after the ignition source is removed,

– occurrence of dripping flaming drops,

– total burning time.

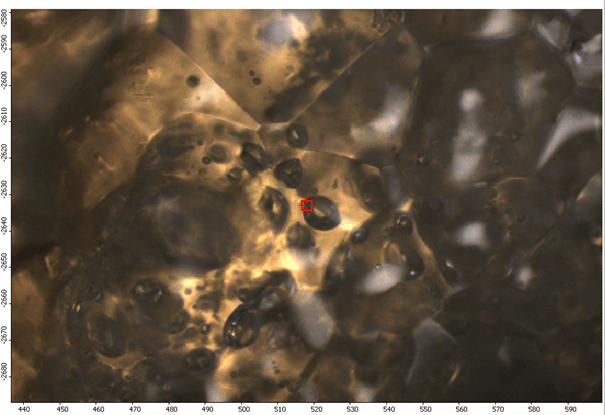

LUMOS II Bruker FT-IR microscope

Technical specifications:

- Measurement techniques: ATR, transmission and reflection

- Detectors: standard TE-MCT and high-sensitivity LN-MCT,

- Analysis of samples up to a height of 40 mm,

- ATR: integrated crystal with automatic pressure control,

- 8x lens for transmission, reflection and ATR measurements.

- Full MIR range: 4000–340 cm⁻¹,

Applications:

- Analysis of multilayer structures (laminates, coatings)

- Examination of defects, impurities, inclusions and faults,

- Mapping the distribution of components in composites and nanocomposites,

- Study of degradation, aging and local chemical processes,

- Study of degradation, aging and local chemical processes,

Quality control and ensuring material compliance.

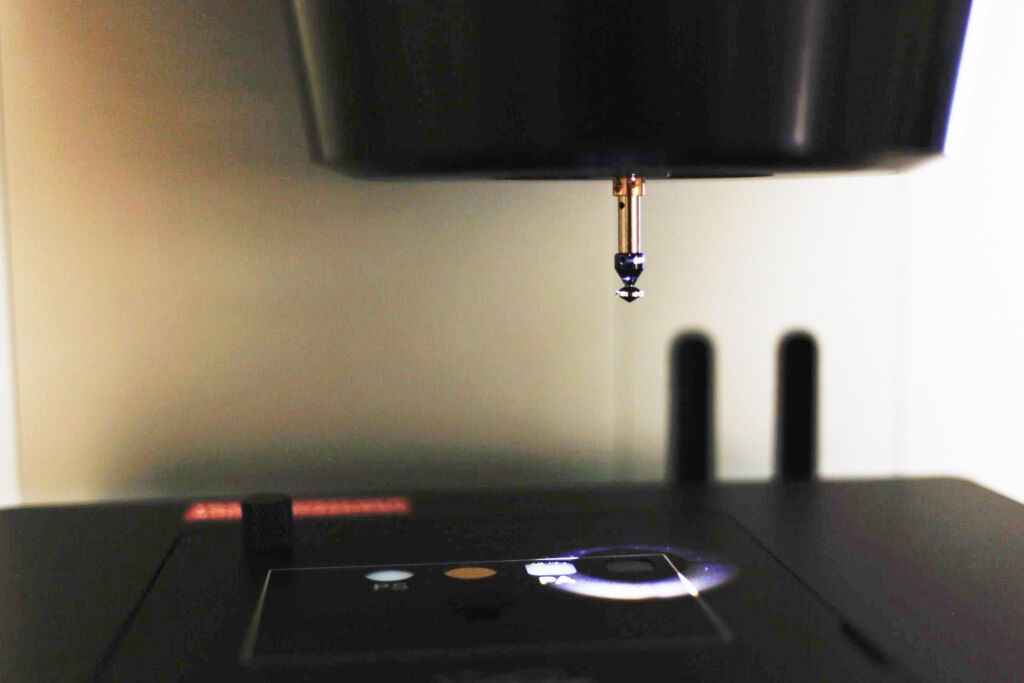

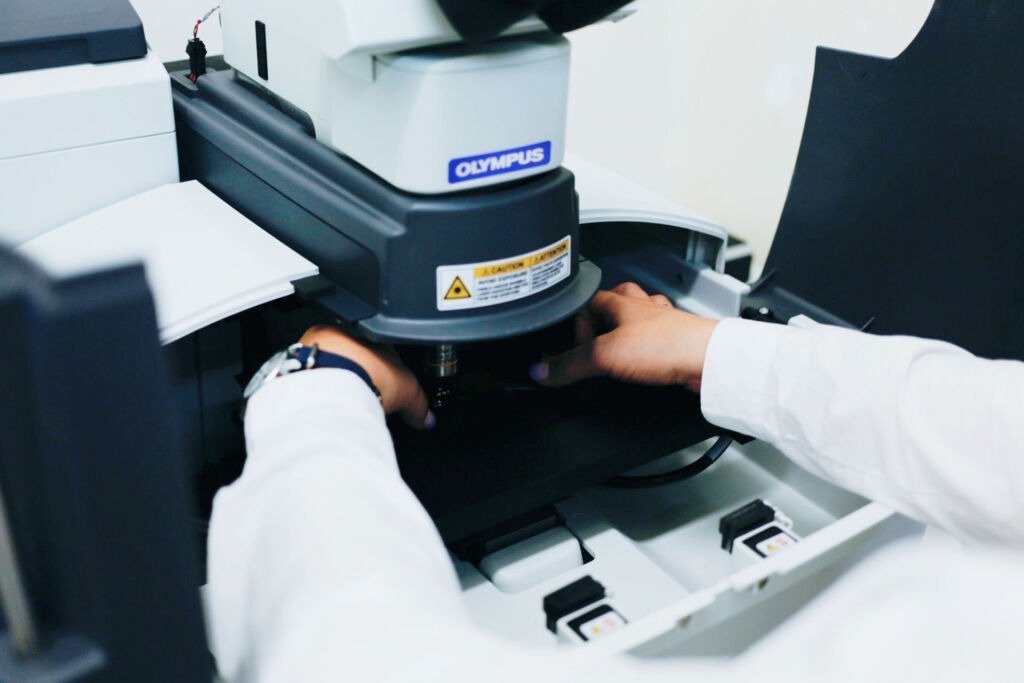

Thermo Scientific DXR3 confocal Raman microspectrometer

Technical specifications:

- Class I laser,

- Laser wavelengths: 532nm and 785nm,

- Microscope objectives with 10x and 50x magnification,

- Automatic fluorescence correction system,

- High spatial resolution (up to ~500 nm),

- Spectral range: 50–3500 cm⁻¹,

- Spectral resolution: 5 cm⁻¹,

- Laser power regulator up to 10mW.

Applications:

- Identification and characterization of polymers – determination of chemical composition, degree of crystallinity.

- Analysis of polymer modifications – monitoring the effect of additives on the chemical structure.

- Characterization of composites – study of phase distribution and interaction, assessment of interfacial adhesion.

- Flammability and degradation process testing – identification of pyrolysis, oxidation and chemical change products.

- Layer profiling – analysis of protective, barrier and fire-resistant coatings on polymers and composites.

- Quality and failure control – detecting impurities, defects, misdoping or degradation in polymeric materials.

Instron 3345

The Instron 3345 is a precision, stationary tensile, compression and bending testing machine.

Key Technical Specifications of the Instron 3345

– Maximum force capacity 5 kN (1125 lbf),

– Testing speed from 0.05 to 1000 mm/min,

– Vertical test area 1123 mm (44.2 in),

– Throat depth 100 mm (3.9 in).

Easy Max 102 Chemical Synthesis Workstation

The station is equipped with two 100 mL reactors in which experiments can be carried out in parallel at temperatures ranging from -10 to 180°C.

IR probes enabling monitoring of chemical processes through in-line analysis.

Possibility of recording and analyzing the infrared spectrum (FTIR) of the reaction mixture in real time.

Key technical parameters

React IR 15 device with DiComp probe 6.35-9.5 mm x 305 mm x 1.5 m (stationary, liquid nitrogen cooled).

React IR 702L device with DiComp probe 6.35-9.5 mm x 305 mm x 1.5 m (mobile, does not require liquid nitrogen cooling).

RC1e calorimetric reactor

A 2L reactor with a precise temperature control system, two dosing pumps, and scales controlling the masses of the reagents fed into the reactor.

It enables precise determination of the thermal effects of chemical reactions and physicochemical processes, determination of the full heat and mass balance of the reactor, and conducting kinetic studies.