Polymer technology research group

Polymer Processing Section

We develop modern polymer materials and refine their processing technologies to support industry in creating more innovative, efficient, and environmentally friendly products. We combine chemistry, materials science, and advanced technologies to deliver ready-to-implement solutions.

CONTACT

Regina Jeziórska, PhD. Sc. Eng.

phone +48 453 056 185

regina.jeziorska@ichp.lukasiewicz.gov.pl

We focus on developing materials that are easy to process, durable, and environmentally friendly. We support companies in optimizing production processes, improving product quality, and implementing recycling technologies, which increases efficiency and reduces environmental impact.

Research offer:

- chemical modifications of thermoplastics by reactive extrusion

- recycling of thermoplastics, including by reactive extrusion

- filling and reinforcing thermoplastics

- biodegradable polymer composites using raw materials of natural origin (wood flour, agri-food waste)

- thermoplastic starch and biodegradable composites containing it

- Arburg 420M Allrounder 1000-250 injection molding machine – equipped with the Priamus injection process monitoring system and injection molds for mechanical testing and cutlery, cups and plates

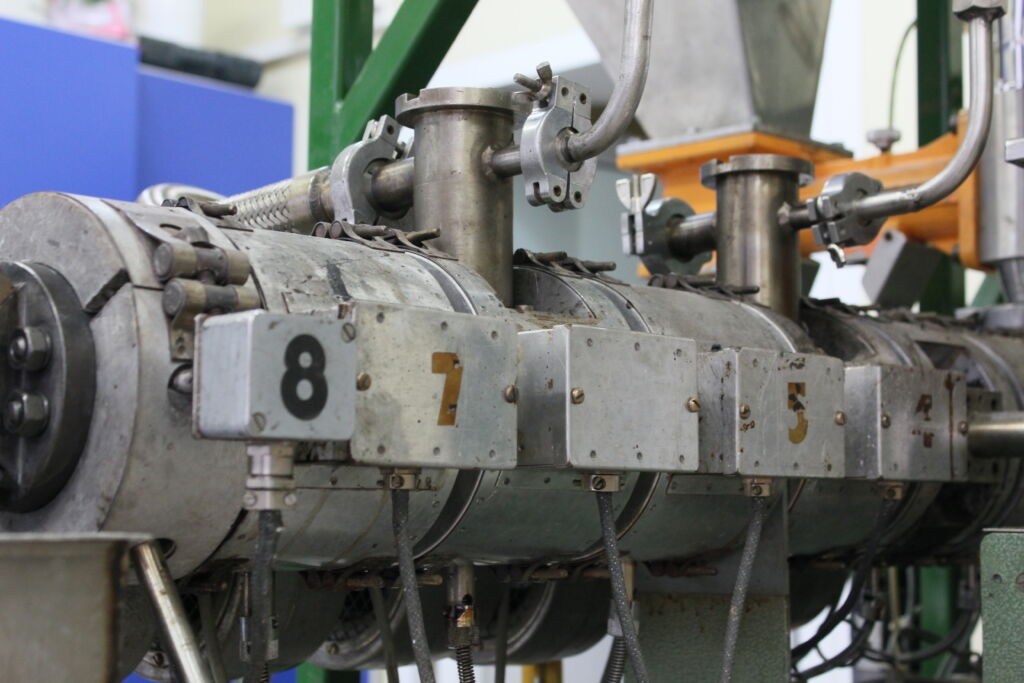

- Berstorff ZE-25-33D twin-screw co-rotating roller extruder – equipped with K-Tron mass dosing unit

- KraussMaffei Berstorff ZE25Ax51D-UTXi-UG co-rotating twin screw extruder equipped with a set of mass feeders; a native starch feeder and a liquid substance feeder

- Co-rotating twin screw extruder, ThermoHaake PTW 16/25D

- Stephan UMC 12 Mixers

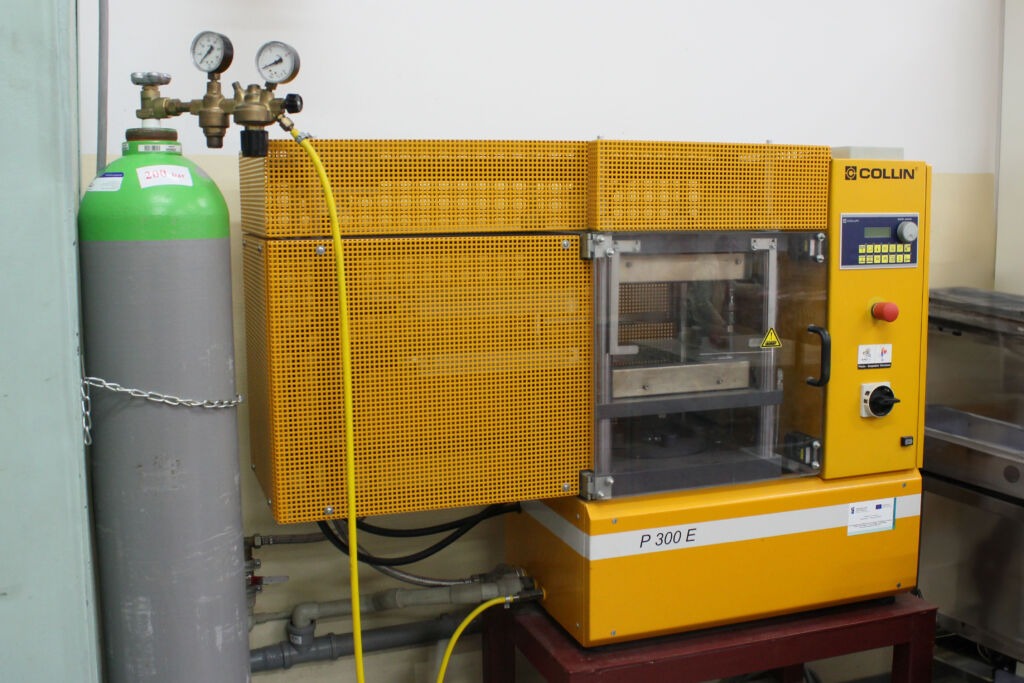

- Dr Collin P 300 E laboratory plate press – equipped with a rapid cooling system for the pressing plates, increasing the efficiency of the device

- Cutting mill, SM100, Retsch – collection vessel capacity: 5 l, sieves: mesh size 0.25; 0.75; 1.5; 4; 8; 10; 20 mm

- Montan MD 11C and Somos TF 10 molecular sieve dryers

- Two-wheeler, Schwabenthan Berlin

- Mytron climate chamber KPK 120

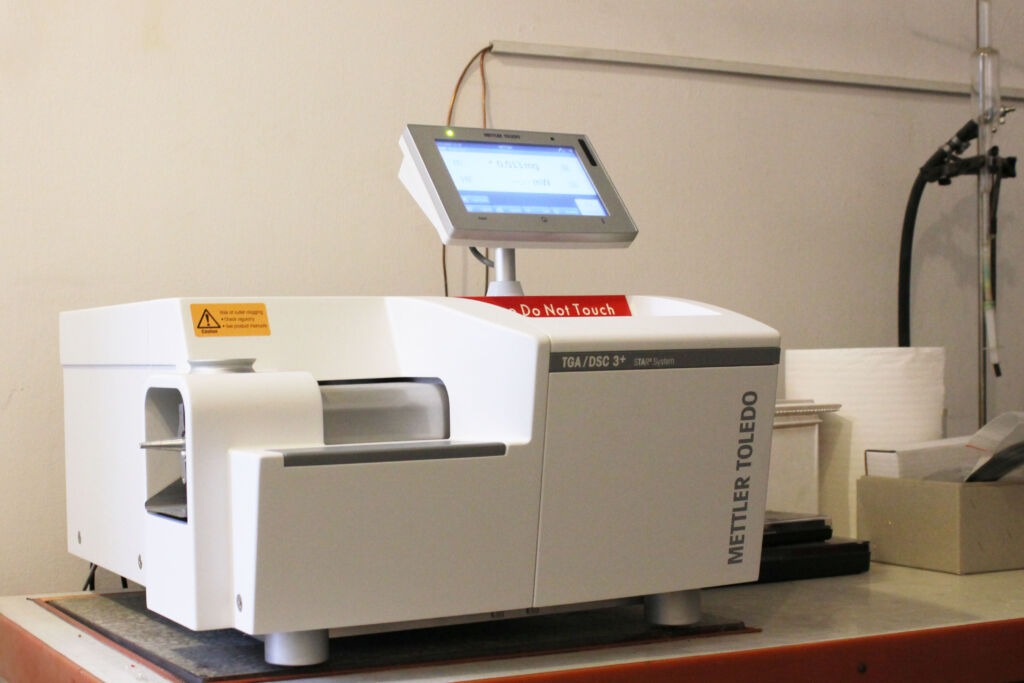

- Thermobalance TGA/DSC+, Mettler Toledo. Temperature range 25—1000°C, max. sample weight – 1 g

- DSC differential calorimeter, Temperature range 30-400°C

- TotalPerm gas vapor permeability test device (O2, CO2, H2O) by ExtraSolution

- Dynamic Rheometrics Spectrometer RDS II, Rheometrics Measurement at temperatures from -160°C to 500°C

- Plastometer (Ceast, Italy type ModularMelt Flow) Control with an accuracy of 0.1°C in the range of 100-400°C; piston load up to 21.6 kg, PN-EN ISO 1133

- Vicat/HDT softening point measuring device CEAST HV3, Measurement at temperatures up to 300°C, PN-EN ISO 306, PN-EN ISO 75-1

- Instron 5500R testing machine A machine for testing the strength of materials during tension and bending, equipped with 2 measuring heads: up to 0.5 kN, 5 kN, 100 kN, PN-EN ISO 527–2 and PN-EN ISO 178 standards

- Shore hardness tester – hardness measurement scale A and D, according to PN EN – ISO 868

- Zwick hardness tester – Rockwell ball hardness measurement according to PN EN ISO 2039

- Młot udarowy Zwick – zakres pomiarowy do 4 J, wg Charpy’ego z karbem lub bez karbu wg normy PN-EN ISO 179−1, udarności wg Izoda PN-EN ISO 180

- Laboratory reactors and autoclaves