Polymer technology research group

Biomaterials Section

We design modern functional biomaterials that are safe, environmentally friendly and ready for practical application.

Our solutions respond to contemporary challenges – from fighting infections, through supporting tissue regeneration, to creating biodegradable materials – while maintaining the principles of the circular economy and supporting the green transformation of industry.

CONTACT

Katarzyna Łęczycka-Wilk, PhD. Sc.

phone +48 453 056 203

katarzyna.leczycka-wilk@ichp.lukasiewicz.gov.pl

We design biodegradable films and biopolymer coatings made from starch, chitosan, cellulose, and other materials. Thanks to green plasticisers, our materials are flexible, environmentally friendly, and compliant with green chemistry principles.

We use waste from the agri-food industry, such as fruit peels and seeds, as fillers and sources of bioactive substances, giving materials additional functionalities while maintaining their eco-friendly nature.

Research offer:

BIODEGRADABLE AND COMPOSTABLE PACKAGING

We design biodegradable films and biopolymer coatings made from starch, chitosan, cellulose, and other materials. Thanks to green plasticisers, our materials are flexible, environmentally friendly and compliant with the principles of green chemistry. We use agricultural and food industry waste, such as fruit peels and seeds, as fillers and sources of bioactive substances, giving the materials additional functionalities while maintaining their eco-friendly nature.

ACTIVE AND SMART PACKAGING

Our active films extend the freshness of food products – up to ten times longer than traditional packaging. They regulate moisture and gas permeability and can release bioactive substances with antifungal and antibacterial properties. This solution reduces food waste and lowers the environmental footprint.

EDIBLE COATINGS

We develop edible coatings that can be consumed together with the product. They protect food, preserving its nutritional value, reducing drying and spoilage, and at the same time reducing packaging waste. Laboratory tests have shown that our solutions effectively extend the freshness of fruit and vegetables – for example, cherry tomatoes coated with the coating remained fresh for 21 days, almost twice as long as uncoated products.

MODIFICATION OF BIODEGRADABLE POLYMERS

We develop biopolymer materials with carefully selected fillers and functional additives, which allows us to modify their mechanical and thermal properties as well as their permeability to gases and water vapour. This enables us to adapt the materials to various applications – from packaging and medical devices to agriculture – while minimising their environmental impact.

SMART POLYMERS WITH SHAPE MEMORY

We design shape memory polymers that can ‘remember’ their original shape and recover it under the influence of stimuli such as temperature or magnetic fields. These materials are used in biomedical engineering – including implants and tissue scaffolds – and in industry, where precisely controlled functional properties are required.

POLYMERS WITH ANTIBACTERIAL PROPERTIES

We develop active materials that effectively neutralise microorganisms. This allows them to be used in medicine, the food industry, or as antibacterial surfaces in public places. We combine polymer chemistry with biotechnology to create safe, durable, and effective solutions.

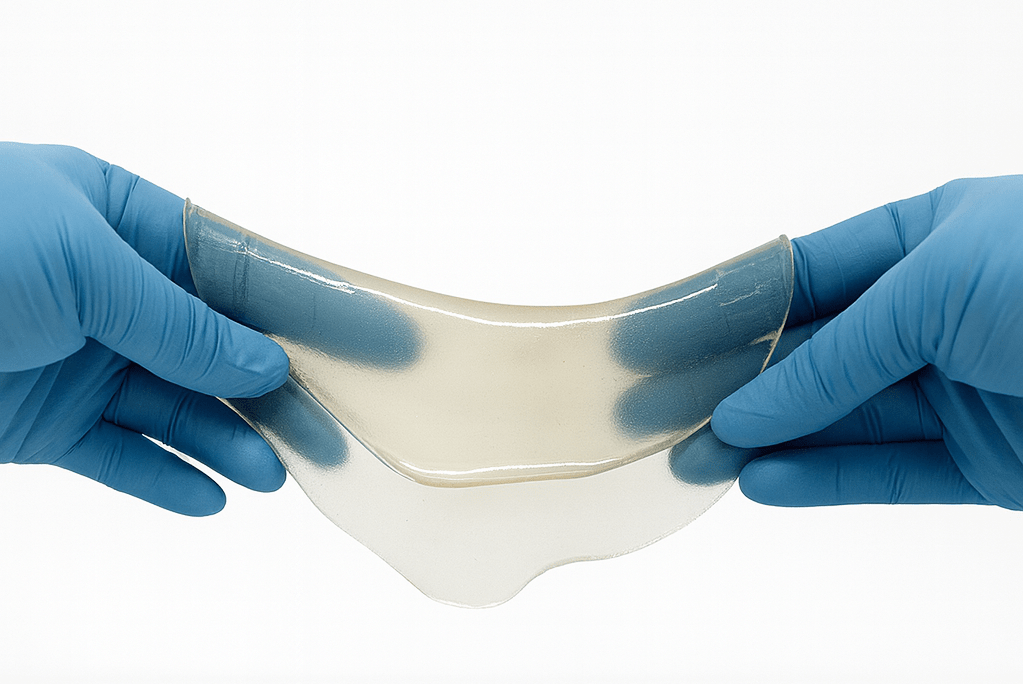

MEDICAL BIOMATERIALS

We develop innovative hydrogels based on natural polymers, intended, among other things, for dressings supporting wound treatment. Thanks to the possibility of introducing active substances into their structure, we give them targeted effects – anti-inflammatory, antibacterial or supporting the wound healing process.

Analytical methods offered

We offer a wide range of methods for characterising biological materials and biomaterials, including spectroscopic and microscopic techniques, chemical analysis and biological testing. This allows us to comprehensively assess the mechanical, chemical and biological properties of our materials.

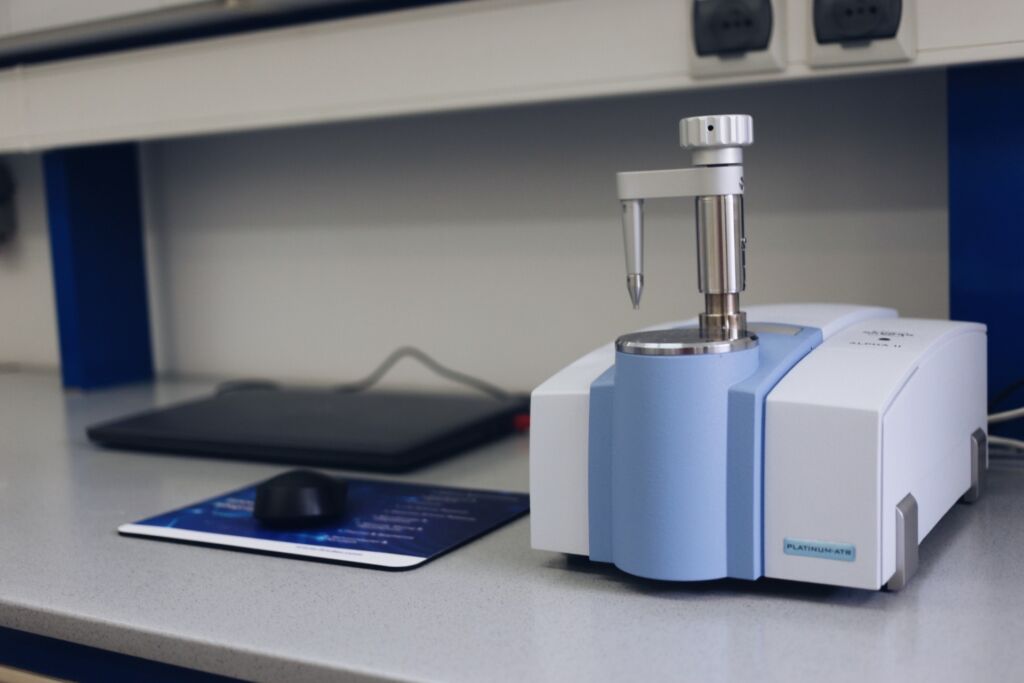

- FTIR spectroscopy – identification of functional groups and intermolecular interactions

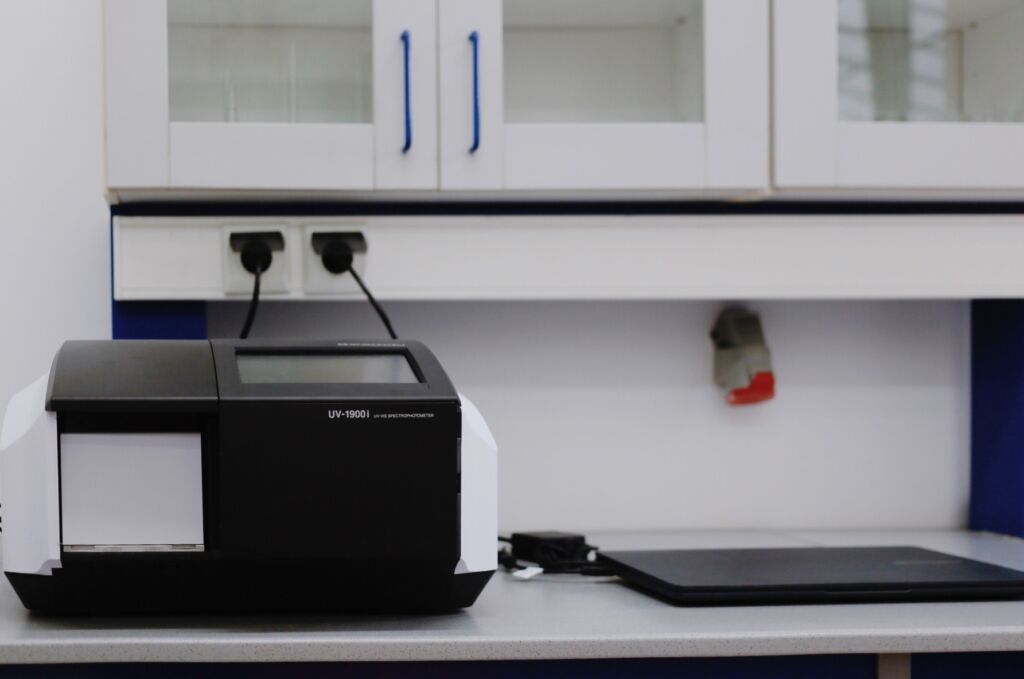

- UV-Vis spectroscopy – determining the concentration of absorbing substances in the UV-Vis range and monitoring photochemical processes.

- GPC/SEC exclusion chromatography with quadruple detection – analysis of polymers and macromolecules, which, thanks to the use of quadruple detection (RI, UV, MALS, Visc), allows for precise determination of molar mass and its distribution, spatial structure and intermolecular interactions.

- Spektrometria mas MALDI – oznaczanie masy cząsteczkowej, ocena składu i czystości próbek oraz identyfikacja polimerów, białek i peptydów.

- Measurement of barrier properties – permeability to gases (O2, CO2 and H2) and water vapor

- Determination of antioxidant properties – determining the ability of a substance to neutralize free radicals and delay oxidation processes.

- Moisture determination – determining the content of water and volatile substances

- Particle size analysis – measurement of solutions, pastes, gels and even solid samples in bulk form.