CHEMICAL TECHNOLOGY RESEARCH GROUP

Process Modeling Section

We prepare process models, select operating parameters, assess profitability and technological risks, and then verify solutions on a laboratory, semi-technical and large-scale laboratory scale.

This enables our partners to develop new technologies faster, reduce costs, and implement processes with higher efficiency, stability, and security.

CONTACT

Zbigniew Laskowski, PhD. Sc. Eng.

phone +48 453 056 224

zbigniew.laskowski@ichp.lukasiewicz.gov.pl

Offer:

CHEMICAL MARKET ANALYSIS

We monitor national and global trends, assess the profitability and availability of raw materials, examine technological developments, and forecast changes affecting the chemical sector. We provide analyses to support strategic, investment, and research decisions.

ECONOMIC ANALYSIS OF TECHNOLOGICAL PROCESSES

We assess the cost-effectiveness of technological solutions, analyse investment and operating costs, perform variant comparisons, and support decisions regarding the selection of technologies in the context of their industrial implementation.

IMPLEMENTATION OF RESEARCH, DEVELOPMENT AND IMPLEMENTATION WORK

We design and develop innovative chemical processes, prepare technological concepts, carry out pilot projects and participate in implementations in an industrial environment. Our activities cover the entire cycle — from concept analysis, through modelling and optimisation, to implementation support.

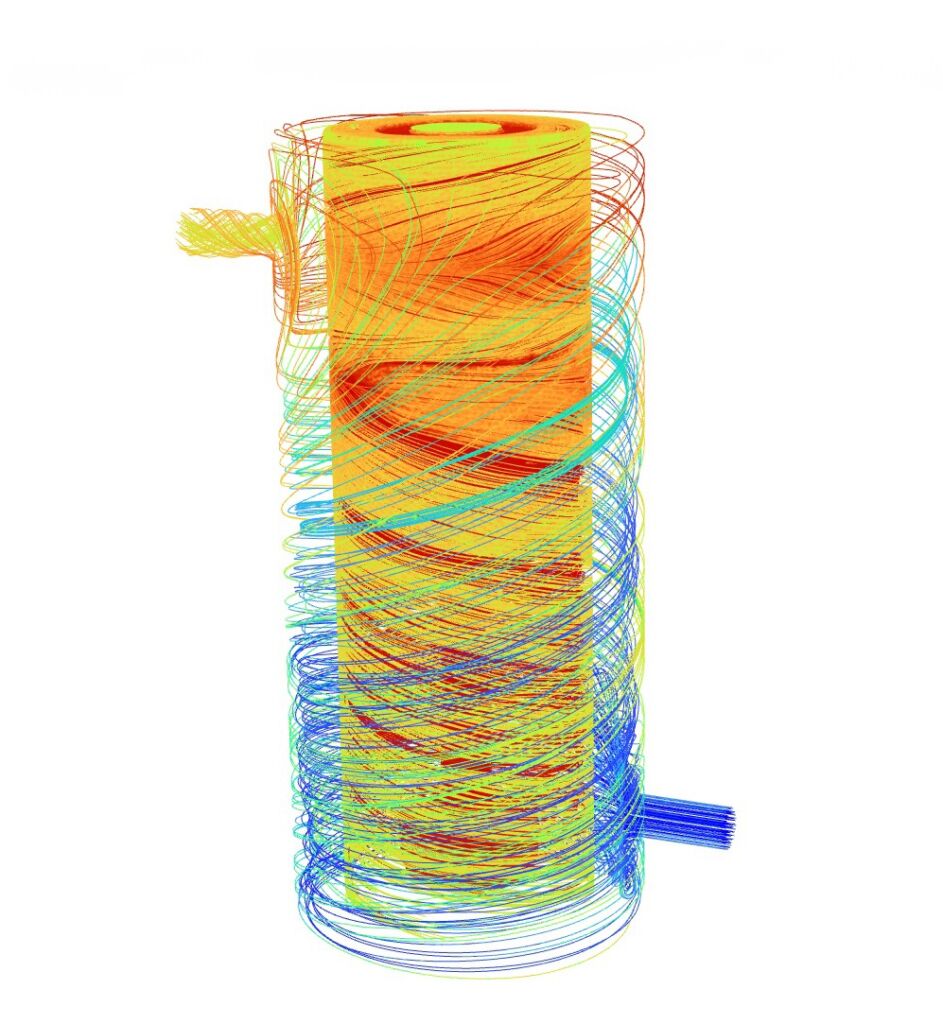

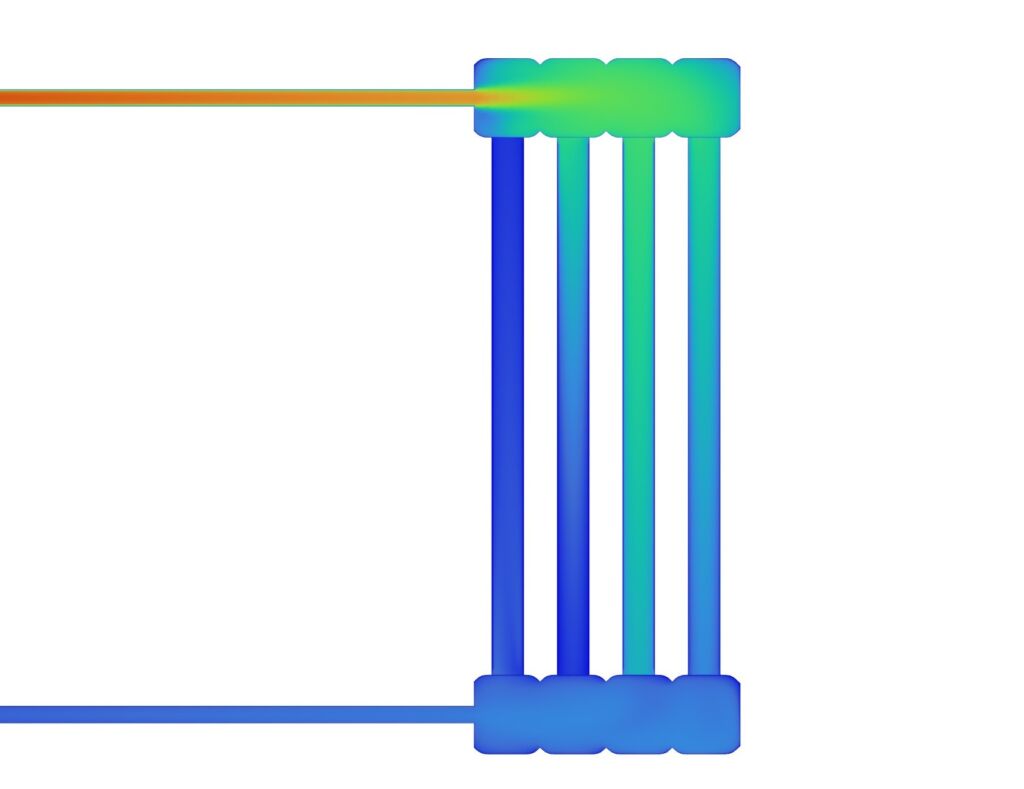

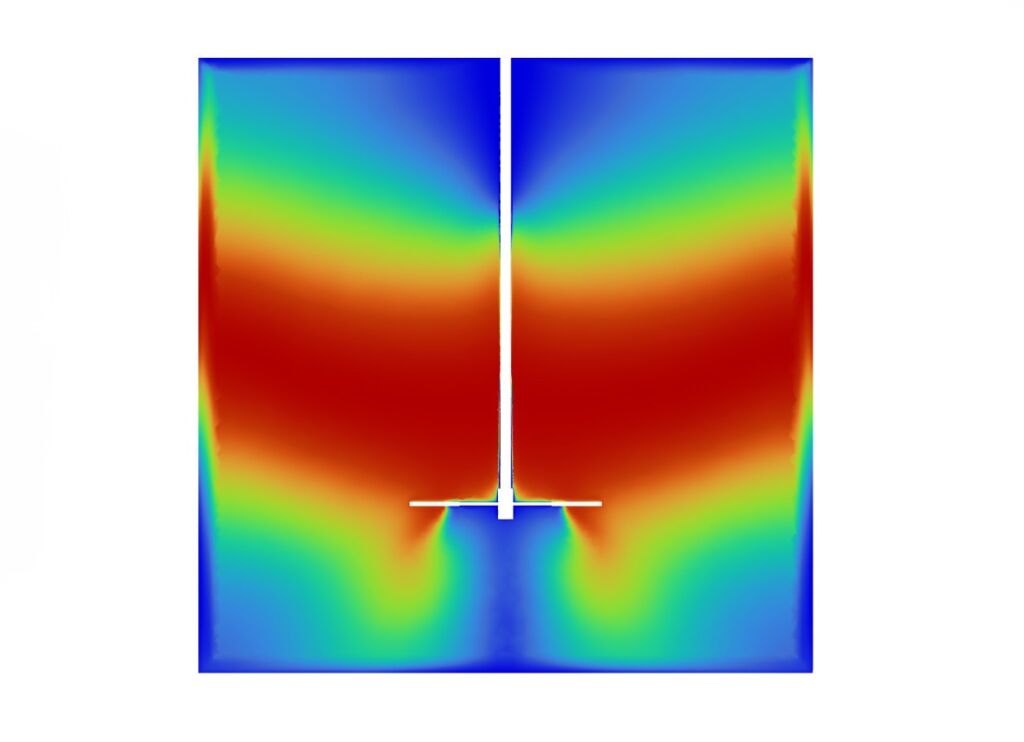

ADVANCED MODELLING AND OPTIMISATION OF TECHNOLOGICAL PROCESSES

We create detailed models of chemical processes and accompanying phenomena using professional numerical tools such as ANSYS Fluent, ChemKin and ChemCad.

As part of modelling:

- we analyse flows, heat exchange, chemical reactions and mass transport in complex process systems;

- we identify key parameters determining the efficiency and safety of installations;

- we test various operational and design scenarios without the need for costly physical experiments;

- we identify potential problems and areas of process losses at the design stage;

- we seek configurations that ensure maximum efficiency, energy cost reduction, emission reduction and increased operational stability of the installation;

- We support the scaling of processes from the laboratory level to pilot and industrial installations.

Modelling is the foundation of modern process engineering for us — it allows us to shorten the time needed for experiments, reduce implementation costs and significantly lower technical risks. Thanks to simulations, we are able to predict the behaviour of processes in conditions that would be difficult or impossible to reproduce experimentally.