What do you know about powder coatings? Certainly that powder coatings do not emit VOCs, meet the criteria set for coating products by modern industry, such as environmental compliance… But… They can always be improved. This is the topic that researchers have addressed in the publication (TOP 10 Scopus) “Antimicrobial Powder Coatings Based on Environmentally Friendly Biocides,” ACS Sustainable Chem. Eng. Co-authors of the paper are Michał Kędzierski, Ph.D., and Katarzyna Bieniek, M.Sc., of the Polymer Synthesis and Modification Section.

Let’s try to introduce the subject. Conventional thermoset powder systems have good properties, but their disadvantage is their high curing temperature (180-200°C), which limits their use for painting heat-sensitive materials such as wood, MDF and plastics. UV-curable powder coatings offer a solution to this problem.

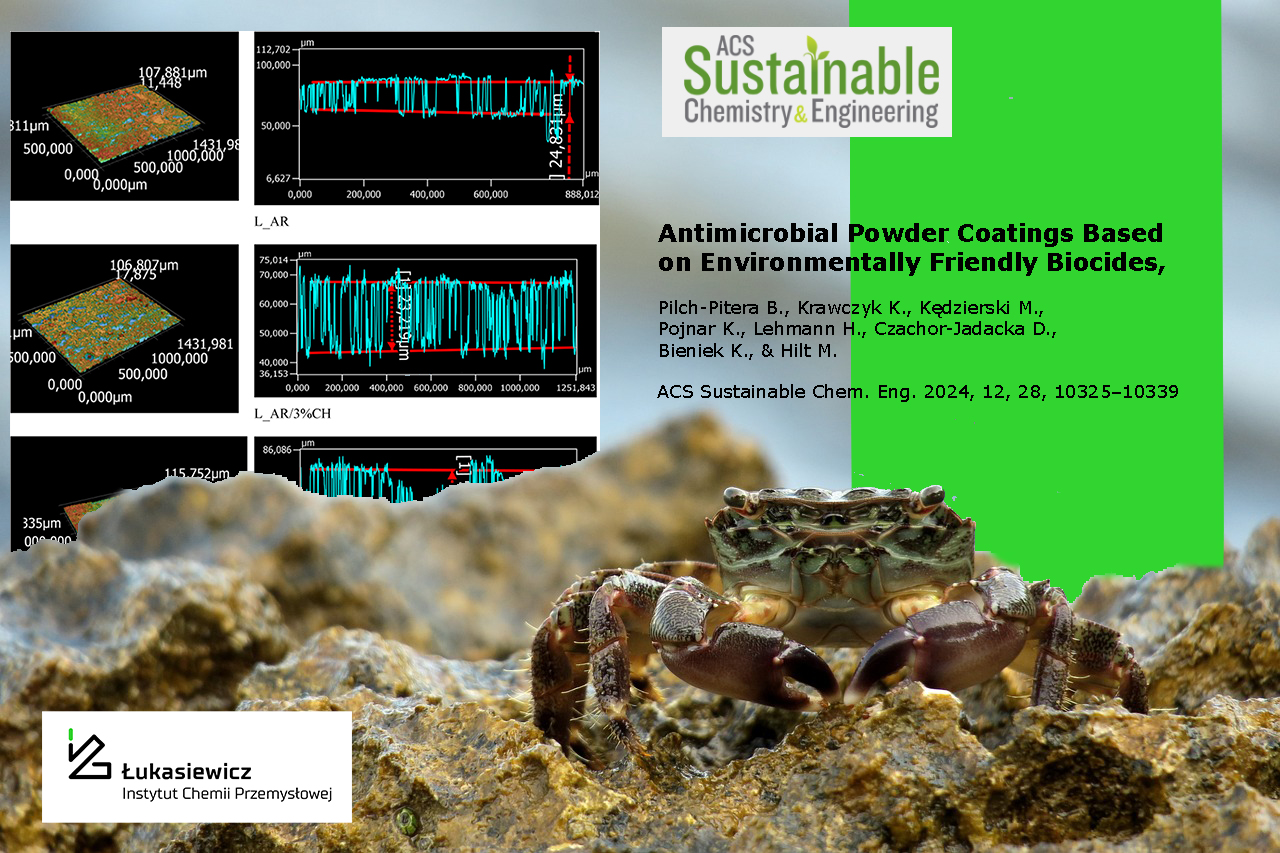

The publication describes UV-curable powder coatings with antibacterial properties against E.coli and S.aureus strains. The coatings were obtained using an acrylic resin containing epoxy groups and an environmentally friendly biocide, chitosan, as a binder.

As Michał Kędzierski, Ph.D. Sc. Eng., explains, the aim of the work was to replace silver additive in powder coatings, which is commonly used to impart antimicrobial properties to coating materials. Its use, however, poses problems related to bioaccumulation – when used intensively – and the possible immunotoxic inflammatory potential of nanosilver particles, as indicated by the results of some studies.

It turned out, as described in the paper, that the addition of 2-3 wt% chitosan does not cause any deterioration in the performance of the coatings, which were tested for scratch resistance, hardness, adhesion, roughness and gloss. Moreover, it gives very favorable results for the coating’s antibacterial activity, while improving its resistance to biocide leaching in contact with water.

It should be added that among biopolymers, chitosan is one of the most promising materials. This aminopolysaccharide, obtained by deacetylation of chitin, is the main component of the outer skeletons of marine crustaceans and the outer walls of fungi. Chitosan is known to be biocompatible, biodegradable and non-toxic to humans and higher organisms. It is also an effective antibacterial and antifungal agent.

***

Work on antimicrobial powder coatings using natural substances with biocidal activity continues under the Polish-German Microsafecoatings project (Cornet program), in which our Institute participates (more about the project: here). The project manager for the part carried out by Łukasiewicz – ICI is Michał Kędzierski, PhD. Sc. Eng.

publication link: https://doi.org/10.1021/acssuschemeng.3c07721

By: Iwona Lisek-Woubishet