Polymer technology research group

Vinyl Polymers Section

We specialise in the synthesis, modification and application of vinyl polymers, including polyvinyl chloride, developing materials with improved properties, greater durability and reduced environmental impact.

By combining innovative technologies and advanced analytics, we help companies implement practical solutions that increase productivity and product quality.

CONTACT

Marcin Kumosiński, M. Sc. Eng.

phone +48 453 056 210

marcin.kumosinski@ichp.lukasiewicz.gov.pl

Our approach covers the entire life cycle of the material – from the development of its composition, through processing, to its final functional properties.

Our solutions are used in construction, electrical engineering, packaging, and medicine, among other fields.

Research offer:

SYNTHESIS AND MODIFICATION OF VINYL POLYMERS:

- New methods of radical polymerisation using suspension and emulsion techniques. Atom transfer radical polymerisation (ATRP) and radical polymerisation with controlled chain transfer (RAFT).

- Designing gradient copolymers, block copolymers and polymers with controlled structure.

- Chemical modification involving, for example, the grafting of acrylates or other compounds to improve weather resistance and increase chemical and thermal resistance.

- Development of new formulations to improve the physicochemical properties of PVC and increase productivity per unit of time.

- Development and testing of new substances in synthesis processes.

- Modification of PVC production facilities, including adaptation of processes to new quality and environmental requirements, and improvement of efficiency.

- Optimisation of processes towards reducing emissions and striving for more environmentally friendly production methods that minimise environmental impact.

DRY BLEND RESEARCH:

- Optimisation of recipes and mixing technologies for products with improved mechanical and functional properties.

- Development of new processing additives and testing of new products.

- Research into reducing the flammability of PVC products and developing mixtures that comply with environmental standards.

RHEOLOGICAL STUDIES OF VINYL POLYMERS:

- Measurement of plasticisation and gelation parameters to assess material processability and improve the properties of the final product.

- Measurement of thermal stability under processing conditions to assess the material’s resistance to thermal degradation.

- Measurement of processing time and rheological properties of the alloy in order to optimise technological processes.

- Torque measurement to assess alloy viscosity and analyse the processing process.

- Measurement of processing temperatures to determine the optimal process conditions for obtaining the desired material properties.

- Measuring the homogeneity of the mixture to assess the uniformity of the distribution of components and improve product quality.

RESEARCH INTO THE PROCESSING OF VINYL POLYMERS:

- Polymer alloy viscosity test to assess the fluidity of the material during extrusion.

- Extrudability tests:

– Measurement of worm torque to analyse material resistance during processing.

– Thermal stability testing to assess resistance to thermal degradation.

– Extrusion pressure analysis – pressure measurement at the flow through the head.

– Testing the quality of the product surface by checking for smoothness and defects (ribbon extrusion; rod extrusion: ∅ 3.0 mm, ∅ 4.0 mm, ∅ 5.0 mm.)

– Temperature profile analysis – temperature monitoring in extruder zones.

– Performance measurement – determining the amount of processed material.

– Thermal deformation resistance test – analysis of dimensional stability after exposure to high temperatures.

– Analysis of results and correlation with reference samples – comparison with reference materials to assess the quality and stability of the process.

- Analysis of results and correlation with reference samples – comparison with reference materials to assess the quality and stability of the process.

Full control over the process: Thanks to our research at every stage of the process, we are able to deliver materials with optimal properties.

Modern technologies: We have the latest equipment for polymer testing, which ensures precise and reliable results.

Compliance with environmental requirements: Our solutions are environmentally friendly, minimising the impact of production on the environment.

We have modern research facilities that enable comprehensive analyses and tests of polymer materials. Our equipment allows for precise testing under various temperature and pressure conditions, supporting the development of innovative technologies.

Laboratory equipment includes:

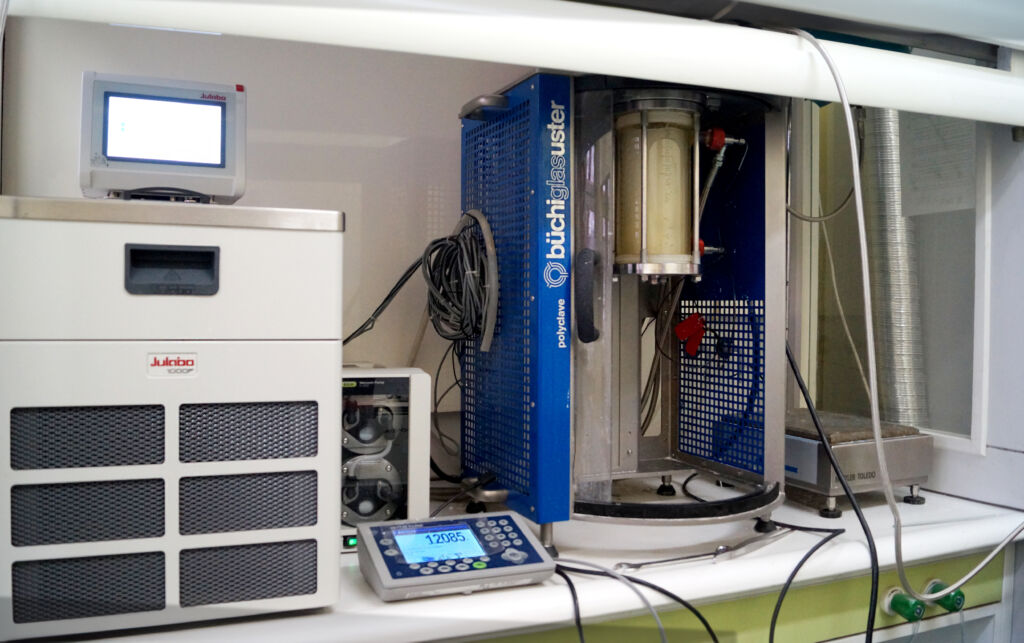

- Polyclave 1.5-litre glass reactors – temperature range: -20°C to 250°C, pressure up to 12 bar, fully equipped and calibrated.

- Hot-cold mixer (Plasmec).

- MetaStation 4E – torque rheometer with software and internet connection.

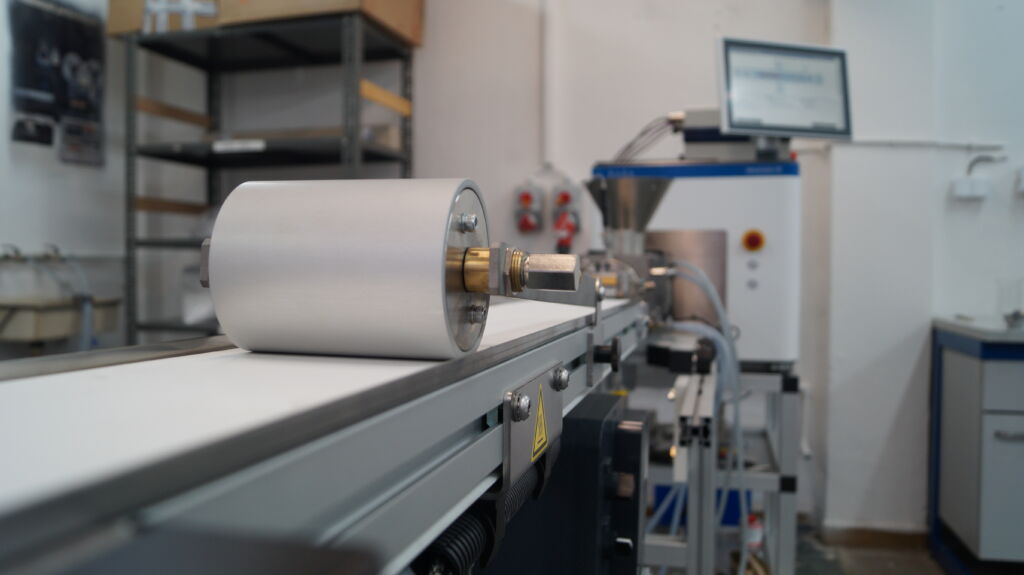

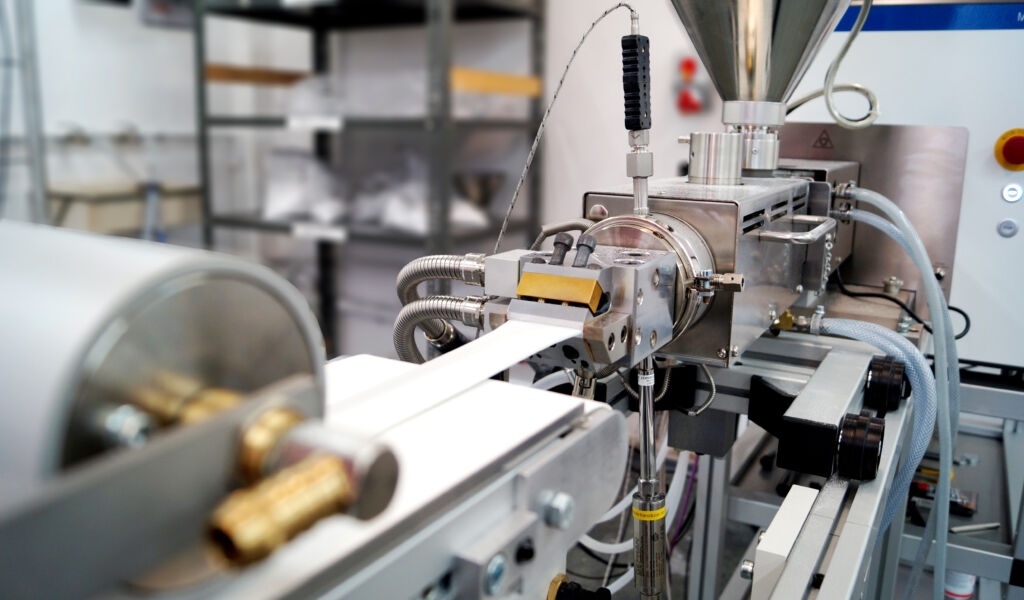

- CTSE conical twin-screw extruder (counter-rotating).

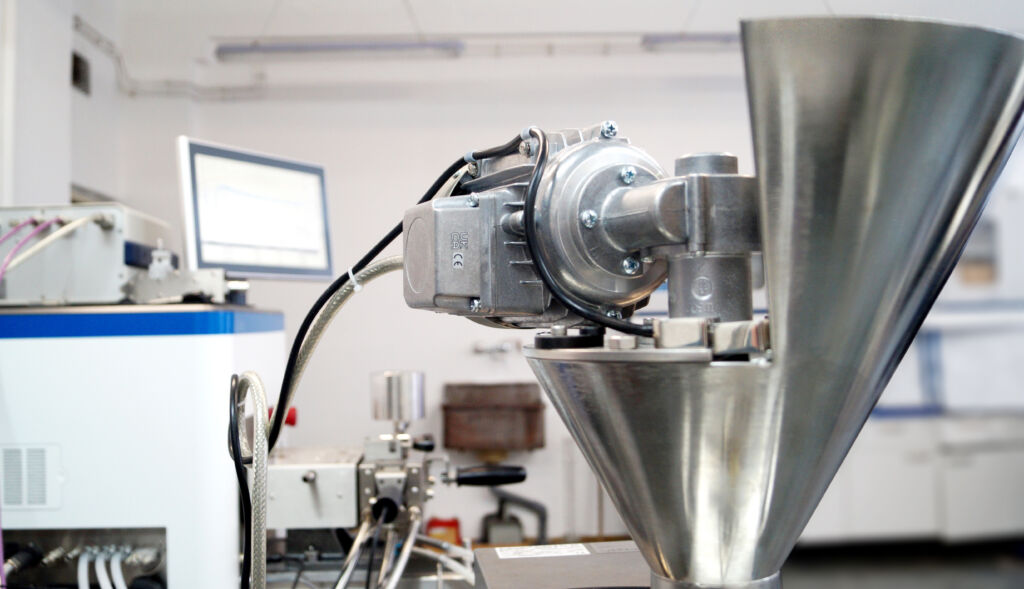

- Vertical screw feeder.

- Extrusion heads, including:

- slotted, flexlip type (nozzle dimensions: 50 x 0.05 to 2.0 mm),

- spindle with a 2 ¾” threaded ring and interchangeable nozzles (Ø 3.0 mm, Ø 4.0 mm, Ø 5.0 mm).

- Planetary mixer P 600.

- 50 EHT measuring crumpler.

- Conveyor belt.

- Cooling bath.

- Granulator.

- Brabender-MetaBridge – advanced data correlation software.

- Fluidised bed dryer.

- Measuring equipment:

- reduced viscosity number,

- thermal stability of different methods,

- colours in space L, a, b,

- transverse resistivity.

Thanks to such advanced research facilities, it is possible to conduct a wide range of research on the properties of vinyl polymers, which supports the development of innovative materials and technologies.

Polyclave 1.5 litre glass reactor (2 sets)

Plasmec hot-cold mixer

MetaStation 4E – Torque rheometer, 50 EHT measuring crumpler

MetaStation 4E – Torque rheometer, CTSE twin-screw extruder

Analytical research

- Density of plastics (PN-EN ISO 1183-3)

- Determination of bulk density (PN-ISO 60)

- Volume resistivity (PN-EN IEC 62631-3-1)

- Colour of plastics and processing additives in the Hunter L. a. b, CIELab L* a* b*,C*,h* system; Determination of whiteness and degree of yellowing

- Determination of K number – reduced viscosity of PVC (PN-EN ISO 1628-2)

- Sieve analysis (PN-EN ISO 4610)

- Plasticiser plasticisation time (drying time) (own method)

- Extrudability test and plastic granulation on a twin-screw extruder (own method)

- Gelling time of dry mixes (own method)

- Thermal stability of PVC PN-C-89265-4.

- Testing resistance to plasticiser migration into LDPE (PN-EN ISO 177)

- Testing resistance to plasticiser migration into model fluids (ASTM D1239 / PN-EN ISO 13130)

- Determination of water absorption (PN-EN ISO 62)

- Determination of mass loss of plastics (PN-C 89265)